Blog

October 31, 2024

What are medical instruments and how they are produced

Medical instruments are essential tools in healthcare, playing a critical role in the diagnosis, treatment, and monitoring of patients. These instruments range from basic devices, like stethoscopes and thermometers, to complex machinery, such as MRI machines and robotic surgical systems. Their importance cannot be overstated, as they directly impact the quality and safety of medical care. This article explores the significance of medical instruments, their applications, and the key aspects of their manufacturing.

Importance of Medical Instruments

- Accurate Diagnosis

Medical instruments are indispensable for accurate diagnosis. For example, stethoscopes allow doctors to listen to the heart and lungs, helping to identify potential issues, while X-ray machines provide a visual of the bones and tissues inside the body. These tools help healthcare professionals detect diseases early, leading to faster and more effective treatment. Diagnostic devices, like blood pressure monitors, ECG machines, and blood glucose meters, allow for timely detection of conditions such as hypertension, heart disease, and diabetes, ultimately improving patient outcomes. - Enhanced Treatment and Surgical Procedures

Surgical instruments, such as scalpels, forceps, and scissors, are critical in carrying out surgeries safely and efficiently. Modern advancements have led to the development of robotic-assisted surgical systems that enable minimally invasive procedures, reducing recovery time and minimizing risks for patients. Instruments like endoscopes allow surgeons to examine internal organs with minimal incisions, improving patient comfort and outcomes. In addition, ventilators and dialysis machines provide life-sustaining support to patients with respiratory and kidney issues, ensuring continuous and effective treatment. - Monitoring and Life Support

Monitoring devices are vital for tracking a patient’s condition over time. Instruments like pulse oximeters, electrocardiograms (ECGs), and blood pressure monitors enable continuous observation of critical health metrics. For patients in critical care, these devices are often connected to a central monitoring system that alerts medical staff of any changes in the patient’s condition. Life-support equipment, such as ventilators, defibrillators, and infusion pumps, are necessary to sustain life in emergencies and intensive care settings. Without these, managing serious health conditions would be challenging. - Improving Healthcare Efficiency

Medical instruments improve healthcare efficiency by allowing faster and more accurate diagnoses, treatments, and surgeries. This efficiency not only saves time but also allows healthcare facilities to serve more patients effectively. For instance, rapid diagnostic kits can deliver results within minutes, reducing patient wait times and streamlining workflow. Portable devices, such as handheld ultrasound machines and wearable monitors, make it easier for healthcare providers to offer care in remote or resource-limited settings, expanding access to quality healthcare.

Types of Medical Instruments

Medical instruments can be broadly categorized into diagnostic, therapeutic, surgical, monitoring, and life-support equipment. Here are a few examples:

- Diagnostic Instruments: X-ray machines, MRI scanners, blood glucose meters, and ultrasound machines.

- Therapeutic Instruments: Dialysis machines, infusion pumps, and nebulizers.

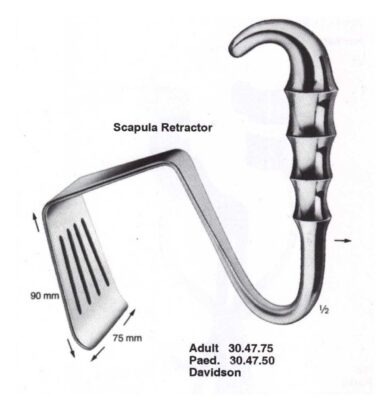

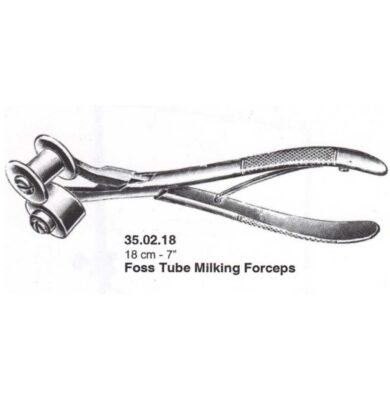

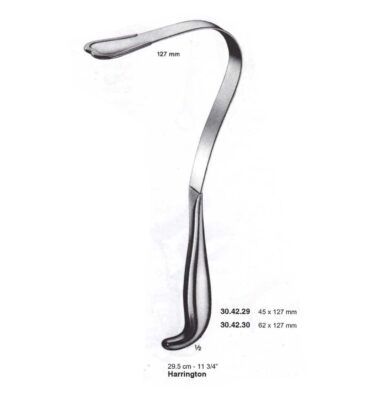

- Surgical Instruments: Scalpels, forceps, retractors, and robotic-assisted systems.

- Monitoring Instruments: ECG machines, pulse oximeters, and blood pressure monitors.

- Life Support Equipment: Ventilators, defibrillators, and pacemakers.

Manufacturing of Medical Instruments

Manufacturing medical instruments requires precision, reliability, and adherence to strict safety and quality standards. The following steps outline the general process:

- Design and Development

The design phase is where ideas take shape based on the requirements of healthcare professionals and regulatory standards. Engineers and designers collaborate to create detailed plans and blueprints. During this phase, factors such as ergonomics, functionality, and patient safety are considered. This stage may involve the use of 3D modeling software to visualize and test the design virtually. - Material Selection

The materials used in medical instruments must be biocompatible, durable, and easy to sterilize. Metals, such as stainless steel, are commonly used for surgical instruments because of their strength and resistance to corrosion. Plastics, ceramics, and silicon are also used, particularly for disposable or single-use instruments. The choice of material is critical, as it impacts both the performance and safety of the instrument. - Prototyping and Testing

Once the design is finalized, a prototype is created. This prototype undergoes rigorous testing to ensure it functions as intended and meets all necessary standards. In this stage, factors such as durability, usability, and safety are tested extensively. Medical instruments must comply with strict regulatory standards, like ISO (International Organization for Standardization) and FDA (Food and Drug Administration) guidelines, which specify the requirements for medical devices and instruments. - Manufacturing Process

Manufacturing processes vary depending on the type of instrument. Common processes include machining, molding, and assembly. For example, surgical instruments are often produced through processes like forging, grinding, and polishing, while plastic components may be made using injection molding. Assembly is a crucial stage, as even minor errors can affect the performance and safety of the instrument. Many facilities incorporate automated assembly lines and quality control systems to maintain high levels of precision and efficiency. - Quality Control and Sterilization

Quality control is integral to the manufacturing of medical instruments. Each device undergoes inspection to ensure it meets all specifications and standards. Any deviation from quality standards can lead to serious safety risks. After quality checks, instruments are sterilized to remove any microorganisms. Common sterilization methods include autoclaving, ethylene oxide gas, and gamma radiation. Sterilization ensures that the instruments are safe to use and free from contamination, which is essential to prevent infections in medical settings. - Packaging and Distribution

Medical instruments must be carefully packaged to maintain sterility and prevent damage during transportation. Packaging must also comply with regulatory standards to ensure it remains intact until the instrument is ready for use. Many instruments are packaged in sterile, single-use containers to simplify logistics and reduce the risk of contamination. Once packaged, the instruments are distributed to healthcare facilities, ready for use in patient care.

Challenges in Medical Instrument Manufacturing

- Regulatory Compliance

Meeting the stringent regulatory requirements set by agencies like the FDA and ISO can be challenging. These regulations are necessary to ensure that medical instruments are safe, reliable, and effective. Compliance requires continuous testing, documentation, and audits, which can be time-consuming and costly. - Technological Advancements

The rapid pace of technological advancements means that manufacturers must continuously innovate to remain competitive. With the emergence of digital health and smart devices, medical instrument manufacturers are increasingly integrating software and connectivity into their products, making them more versatile but also increasing complexity. - Cost and Affordability

Balancing quality with affordability is a major challenge. High-quality materials, stringent testing, and compliance with regulations can drive up production costs. However, making instruments affordable is crucial, especially in regions where healthcare resources are limited.

Tags: healthKabir surgical

Related posts

These tips help you to be healthy

Objectively innovate empowered manufactured products whereas parallel platforms. Holisticly..

Read more